Color Stainless Steel EPS Sandwich Panel Line

Basic Info

Model No.: as your requests

Product Description

Model NO.: as your requests Certification: SGS, ISO9001 Voltage: 380 Volts AC. Suitable Core Material: EPS,Rockwoll,PU Bestworking Temperature: About 25 Pressure: 550 to 700 Kpa Total Weight: 22000-25000 Trademark: WILLING INT′L Specification: ISO9001, CE Standard Feature: Environmental, Fireproof, Light Weight, Metal Panel Customized: Customized Suitable Face Material: Color Steel Sheet Forming Speed: Inverter Adjustment Controller: PC Total Power: 42kw Frequency: 60 Hz (If You Have Your Own Request, We Can Revise Transport Package: Wooden Box and Container Origin: China Pr EPS Sandwich Panel Production Line /Sandwich Panel Line for low price

General description:

WLFM laminator for corrugated sandwich panel is an integrated production line consisting of a Roll Forming Machine and a sandwich panel laminating system. The roll forming machine and the laminating system can be operated separately. The roll forming machine is consists of uncoiler, main body. The laminating system is consists of feeding, glue, heating, laminating and post-cutting.

The whole machine is under control of PLC.

The line can produce single corrugated sheet, and can also laminate the sandwich panel with EPS.

The suitable material is colored Galvanized steel sheet with thickness 0.3-0.6mm,the inserted material is EPS.

II. Technical Parameter

Sandwich Panel Forming Machine QLF-5

IV. Working Flow

Load the coil sheet ( put the coil sheet to the decoiler which is on it's stand) → Guiding ( the coil sheet is

guide to the first roller through the guiding equipment) → Forming → Post cutting( under control of

PLC, adopt encoder to meet the set length, automatic cutting) → panels come out ( above steps

calls step ) →

→ glue adding (paint glue to the surface of coil sheet evenly)

→ feed top coil sheet → folding → glue adding

→ feed EPS panel → add glue to EPS panel → upper and lower roller of the laminator tighten

and roll → heating → groove making → post cutting (under control of PLC, adopt encoder to

meet the set length, automatic cutting) → sandwich panel come to the supporting table.

Our services:

1. Professional engineers are available to be sent to the customers' factory to install and debug the machines and train the staff how to operate and maintain the machines.

2. We can design different kinds of profiles and fittings for machine, as per customer's requirements. You can send me the profile drawing and we will design the machine for you.

3. Every process will be checked by responsible QC which insures every product's quality.

4. Professional packing teams which keep every packing safely.

(1) Rollers are put on anti-rust oil and packed by bubble wraps; some other electric parts are packed by bubble wraps as well.

(2)The oil hose and electric wires ae marked, and easy to be connected when used;

(3)In container loading, sea-worthy, well fixed by wire rope, wooden block and nails.

5. One-year warranty will be assured for all our machines. Moreover, We promise to provide permanent technical support and after-sales service with our customers.

6. We warmly welcome you to visit our factory for more detailed information, inspecting our machines and we will pick you up at HangZhou Railway station.

FAQ:

1. Q: Are you manufacture or trrading company?

A:We are manufacturer & exporter who signed in 2004, and our boss has many years experiences in machinery.

2. Q: Why should I choose you?

A:We are professional manufacture company that could provide the best products for the best price, high quality of services, and credible quality assurance.

3. Q: How does your factory conduct Quality Control and Inspection?

A: We are quite proud of our quality control procedure. It's comply with ISO quality system to control produce from the raw materials received to finishing warehousing. Any imperfect articles are rejected by our quality control.

4. Q: How many kinds of products do you produce?

A: We have produced different kinds of Steel Roof Tile Roll Forming Machine, Corrugated Steel Sheet Roll Forming Machine, C/Z Purlin Roll Forming Machine, Steel Deck Roll Forming Machine, Slitting Line, Cut To Length Line, Press Brake, Shearing Machine, PPGI ,Gi ,PPGL ,Gl, Aluminum Coil. And we also can provide its finished products.

5. Q: Where is your factory located? How can I visit there?

A: Our factory is located in TongXiang, ZheJiang province. We could pick you up from HangZhou East Railway Station or TongXiang Railway Station when you come.

Please feel free to contact me for more up-date information and any queries you have. Best quality machines and services will be provided for you.

Contact us if you need more details on EPS Sandwich Panel Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Eps Sandwich Panel Line、Sandwich Panel Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on EPS Sandwich Panel Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Eps Sandwich Panel Line、Sandwich Panel Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

General description:

WLFM laminator for corrugated sandwich panel is an integrated production line consisting of a Roll Forming Machine and a sandwich panel laminating system. The roll forming machine and the laminating system can be operated separately. The roll forming machine is consists of uncoiler, main body. The laminating system is consists of feeding, glue, heating, laminating and post-cutting.

The whole machine is under control of PLC.

The line can produce single corrugated sheet, and can also laminate the sandwich panel with EPS.

The suitable material is colored Galvanized steel sheet with thickness 0.3-0.6mm,the inserted material is EPS.

II. Technical Parameter

Sandwich Panel Forming Machine QLF-5

| 1.Dimensions | 50000×2600×3000mm |

| 2.Weight | 22T |

| 3.Controlling System | Omron coding machine |

| 4.Main Motor | Cycloid pinwheel reducer |

| 5.Main Motor Power | 2.2kw |

| 6.Productive Speed | 3.38m/min,0-4.05m/min(adjustable) |

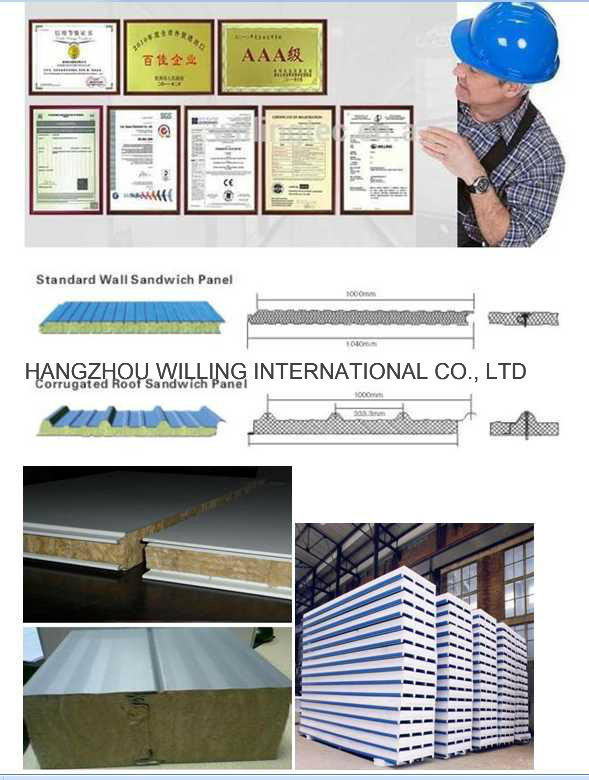

| 7.Panel Types | l EPS core material H board l EPS core material Jack board l EPS core material regular board 950 |

| 8.Voltage | As per customer's request. |

| 9.Composing | Passive feeding machine; profile forming machine; feeding shelf; edge folding machine; compound forming machine; cutting machine; supporter table. Assistant equipment: Color steel slitting machine; cap forming machine etc. |

| 10.Cutting Way | Press knife cutting/Milling cutting/Press knife and milling cutting |

| 11.Roller Material | 45# forge piece chrome over coating |

| 12.Overall Power | 35kw |

| 13.In-phase controller | KMD04B series digital |

| 14.Edge Folding Machine Motor | Minimize cycloid pinwheel reducer |

| 15.Edge Folding Machine Motor Power | 0.37kw |

| 16.Edge Folding Machine Production Speed | 4m/min,0-4.79m/min(adjustable) |

| 17.Profile Forming Machine Motor | Two-stage cycloid pinwheel reducer |

| 18.Profile Forming Machine Motor Power | 2.2kw |

| 19.Profile Forming Machine Production Speed | 4.27m/min,0-5.12m/min(adjustable) |

| 21.Shipping Packing | Naked |

| 22.Applicaton | Roof panel; wall panel |

IV. Working Flow

Load the coil sheet ( put the coil sheet to the decoiler which is on it's stand) → Guiding ( the coil sheet is

guide to the first roller through the guiding equipment) → Forming → Post cutting( under control of

PLC, adopt encoder to meet the set length, automatic cutting) → panels come out ( above steps

calls step ) →

→ glue adding (paint glue to the surface of coil sheet evenly)

→ feed top coil sheet → folding → glue adding

→ feed EPS panel → add glue to EPS panel → upper and lower roller of the laminator tighten

and roll → heating → groove making → post cutting (under control of PLC, adopt encoder to

meet the set length, automatic cutting) → sandwich panel come to the supporting table.

Our services:

1. Professional engineers are available to be sent to the customers' factory to install and debug the machines and train the staff how to operate and maintain the machines.

2. We can design different kinds of profiles and fittings for machine, as per customer's requirements. You can send me the profile drawing and we will design the machine for you.

3. Every process will be checked by responsible QC which insures every product's quality.

4. Professional packing teams which keep every packing safely.

(1) Rollers are put on anti-rust oil and packed by bubble wraps; some other electric parts are packed by bubble wraps as well.

(2)The oil hose and electric wires ae marked, and easy to be connected when used;

(3)In container loading, sea-worthy, well fixed by wire rope, wooden block and nails.

5. One-year warranty will be assured for all our machines. Moreover, We promise to provide permanent technical support and after-sales service with our customers.

6. We warmly welcome you to visit our factory for more detailed information, inspecting our machines and we will pick you up at HangZhou Railway station.

FAQ:

1. Q: Are you manufacture or trrading company?

A:We are manufacturer & exporter who signed in 2004, and our boss has many years experiences in machinery.

2. Q: Why should I choose you?

A:We are professional manufacture company that could provide the best products for the best price, high quality of services, and credible quality assurance.

3. Q: How does your factory conduct Quality Control and Inspection?

A: We are quite proud of our quality control procedure. It's comply with ISO quality system to control produce from the raw materials received to finishing warehousing. Any imperfect articles are rejected by our quality control.

4. Q: How many kinds of products do you produce?

A: We have produced different kinds of Steel Roof Tile Roll Forming Machine, Corrugated Steel Sheet Roll Forming Machine, C/Z Purlin Roll Forming Machine, Steel Deck Roll Forming Machine, Slitting Line, Cut To Length Line, Press Brake, Shearing Machine, PPGI ,Gi ,PPGL ,Gl, Aluminum Coil. And we also can provide its finished products.

5. Q: Where is your factory located? How can I visit there?

A: Our factory is located in TongXiang, ZheJiang province. We could pick you up from HangZhou East Railway Station or TongXiang Railway Station when you come.

Please feel free to contact me for more up-date information and any queries you have. Best quality machines and services will be provided for you.

Contact us if you need more details on EPS Sandwich Panel Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Eps Sandwich Panel Line、Sandwich Panel Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on EPS Sandwich Panel Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Eps Sandwich Panel Line、Sandwich Panel Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : EPS Sandwich Panel Line

Premium Related Products

Other Products

Hot Products

Tile Forming Machine (WLFM28-207-828)Decking Machine (WILLING)Dry Wall Machine (WLFM-C80-U82)Roll Forming Machine (WLFM18-76-988)C Purlin Forming Machine (WLCM-1)Solar Power Bracket Roll Forming MachineSingle Layer CNC Color Steel Forming Machine/ steel corrugated bending machineSingle Layer CNC Color Steel Forming Machine Undulator/ metal roof panel rollerSingle Layer CNC Color Steel roll forming machine /automatic Roof Panel Roll Forming MachineThe New High Speed CNC Cut C Steel roll making machine/zinc roofing sheet making machineSemi-automatic Mortar Production LineSingle Layer CNC Color steel roll forming machine/ steel press machine/ roof tile machineHGC60-221-845B Single Layer CNC Color steel roll forming machine/Roofing Tile Forminggalvanized roofing sheet roll forming machine/ tile roll form machines/ roof tile forming machineColor Steel Composite Board Production Line/ sheet metal roofing machinefull automatic C purlin/ Z purlin roll forming machine