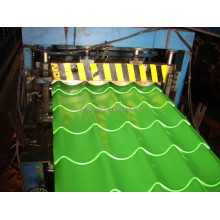

Sales Trapezoidal Dual Level Wall Roof Roll Forming Machine

Basic Info

Model No.: WLFM26-167-835/1002 and 26-200-800/1000

Product Description

Model NO.: WLFM26-167-835/1002 and 26-200-800/1000 Certification: SGS, CE, ISO Customized: Customized Transmission Method: Machinery Material: PPGI,PPGL,Pre-Painted Steel Sheet Thickness: 0.3-0.7mm Max.Forming Speed: 20 M/Min for Trapezoidal,5m/Min for Tile Total Weight: 12 Tons After-Sales Service Provided: Engineers Available to Service Machinery Overseas Transport Package: Sea Worthy Fixed by Wire Rope, Wooden Blocks Origin: China R. P Tile Type: Glazed Steel Condition: New Usage: Roof, Wall, Floor, Ceiling Model Number: Wlfm26-167-835/1002 and 26-200-800/1000 Roller Material: 45#Steel with Chrome Treatment Yield Stress: 235-350 MPa Total Motor Power: 10.5 Kw Warranty: 12 Month Trademark: WILLING INT′L Specification: CE Standard, ISO 9001-2008 HS Code: 84552210 Dual Level trapezoidal Profile Steel tile roll forming machine

High Quality,Compective Price,Series Typies

Welcome Inquiry

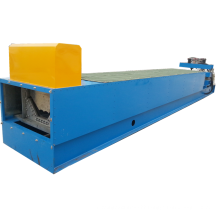

Components for the Machine:

The Roll Forming Machine consists of 5-ton manual uncoiler, infeed guide, fixed position driven forming stations, cutting equipment, hydraulic station, PLC control console, pre-cutter, safety cover, and manual unload product run out table.

Technical Parameters

2. Material of Main Equipment:

Process Sketch

Uncoiling the sheet -Pre-cut -Material feeding ðRoll forming - Measure the length -Cutting the panel -Panels running out to the supporter (optional: Automatic Stacker)

Standard Equipment of Machine

Packaging & Shipping

1.One 40ft container for loading one set machine with manual decoiler;

2.The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3.Spare parts and some small parts packed in plastic tooling box;

4.All Components Fixed by steel wire with Container.

FAQ Q:Are you a manufacturer? A:Yes absolutely. Welcome a lot for your visiting to us. Q:What's the delivery time? A:Normaly will take 60days Q:Do you have after-sale support? A:Yes, we're always here for giving you advice and support for technical details since we have senior technician. Q:Is there quality control when manufacturing the lines? A:Yes, we have a group of team who will be responsible for quality control from laying off the raw material, processing the rollers and the other parts, make treatment on the roller surface and shaft, assembling, testing and packaging. Q:What's your strength comparing to the other supplier? A:We'll supplying you the best quality and service. We'll give you good advise beyond your requirements. The lines are easily for installation and with low mantenance requirements. Contact us if you need more details on Double Layer roll forming machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Dual Level Machine、Dual Level Roof Wall Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

High Quality,Compective Price,Series Typies

Welcome Inquiry

Components for the Machine:

The Roll Forming Machine consists of 5-ton manual uncoiler, infeed guide, fixed position driven forming stations, cutting equipment, hydraulic station, PLC control console, pre-cutter, safety cover, and manual unload product run out table.

Technical Parameters

| Material | Galvanized steel, pre-painted steel, and aluminum. |

| Thickness | From 0.3 mm to 0.7mm. |

| Main Motor Power | 7.5 kw. |

| Hydraulic Power | 3 kw. |

| Feeding Width | 1000/1200mm. |

| Cover Width | 835/1002mm and 800/1000mm. |

| Yield Stress | 235Mpa (33KSI) ~ 350Mpa (50KSI). |

| Total Speed | 20 m/minute for trapezoidal profile; 5m/minute for tile profile. |

| Cutting Tolerance | +/-2.5mm(length≤5000mm); +/-3.0mm(5000mm |

| Manual Uncoiler | capacity is 5 tons. |

| Coil Inner Diameter | 508mm or 610mm. |

| Voltage | 380V, 3 phase, 50 HZ, or customized. |

| Numbers of Station | 17~18 stations. |

| Type of Cutting | roll-formed and length-set profile cutting. |

2. Material of Main Equipment:

| Roller Material | High grade S45C forged steel, coated with hard chrome. |

| Active Shaft Material | High grade S45C carbon wrought steel, diameter 80mm. |

| Electric Elements | PLC control console, touch screen and transducer, from Siemens, Germany. It has data storage function. Other electrical parts, from Schneider Electric, Germany. |

| Cutter Blades | Cr12MoV steel with quenched treatment, hardness HRC58~61, wear-resistance, good steel structure, long life. |

Process Sketch

Uncoiling the sheet -Pre-cut -Material feeding ðRoll forming - Measure the length -Cutting the panel -Panels running out to the supporter (optional: Automatic Stacker)

Standard Equipment of Machine

| 1) | Manual Uncoiler | 1 set | 6) | Hydraulic Station | 1 set |

| 2) | Pre-cuter | 1 set | 7) | PLC Control Console | 1 set |

| 3) | Infeed Guide | 1 set | 8) | Safety Cover | 1 set |

| 4) | Roll Forming Station | 1 set | 9) | Product Support Table | 1 set |

| 5) | Post-cut Equipment | 1 set | 10) | Spare Parts | 1 set |

Packaging & Shipping

1.One 40ft container for loading one set machine with manual decoiler;

2.The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3.Spare parts and some small parts packed in plastic tooling box;

4.All Components Fixed by steel wire with Container.

FAQ Q:Are you a manufacturer? A:Yes absolutely. Welcome a lot for your visiting to us. Q:What's the delivery time? A:Normaly will take 60days Q:Do you have after-sale support? A:Yes, we're always here for giving you advice and support for technical details since we have senior technician. Q:Is there quality control when manufacturing the lines? A:Yes, we have a group of team who will be responsible for quality control from laying off the raw material, processing the rollers and the other parts, make treatment on the roller surface and shaft, assembling, testing and packaging. Q:What's your strength comparing to the other supplier? A:We'll supplying you the best quality and service. We'll give you good advise beyond your requirements. The lines are easily for installation and with low mantenance requirements. Contact us if you need more details on Double Layer roll forming machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Dual Level Machine、Dual Level Roof Wall Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Corrugated/ Trapezoidal Sheet Line

Premium Related Products

Other Products

Hot Products

Tile Forming Machine (WLFM28-207-828)Decking Machine (WILLING)Dry Wall Machine (WLFM-C80-U82)Roll Forming Machine (WLFM18-76-988)C Purlin Forming Machine (WLCM-1)Solar Power Bracket Roll Forming MachineSingle Layer CNC Color Steel Forming Machine/ steel corrugated bending machineSingle Layer CNC Color Steel Forming Machine Undulator/ metal roof panel rollerSingle Layer CNC Color Steel roll forming machine /automatic Roof Panel Roll Forming MachineThe New High Speed CNC Cut C Steel roll making machine/zinc roofing sheet making machineSemi-automatic Mortar Production LineSingle Layer CNC Color steel roll forming machine/ steel press machine/ roof tile machineHGC60-221-845B Single Layer CNC Color steel roll forming machine/Roofing Tile Forminggalvanized roofing sheet roll forming machine/ tile roll form machines/ roof tile forming machineColor Steel Composite Board Production Line/ sheet metal roofing machinefull automatic C purlin/ Z purlin roll forming machine